- Hogar

- Soluciones

- Professional System Control Solution of Industrial Washing Machine Provided by AC70

Professional System Control Solution of Industrial Washing Machine Provided by AC70 Solución

Descripción general

- Descripción general

- Características y Beneficios

- Productos relacionados

- Casos relacionados

- Noticias y eventos relacionados

- Soluciones relacionadas

- Contacta con nosotros

Professional System Control Solution of Industrial Washing Machine Provided by AC70 Solución

Características y Beneficios

Part 1. Summary

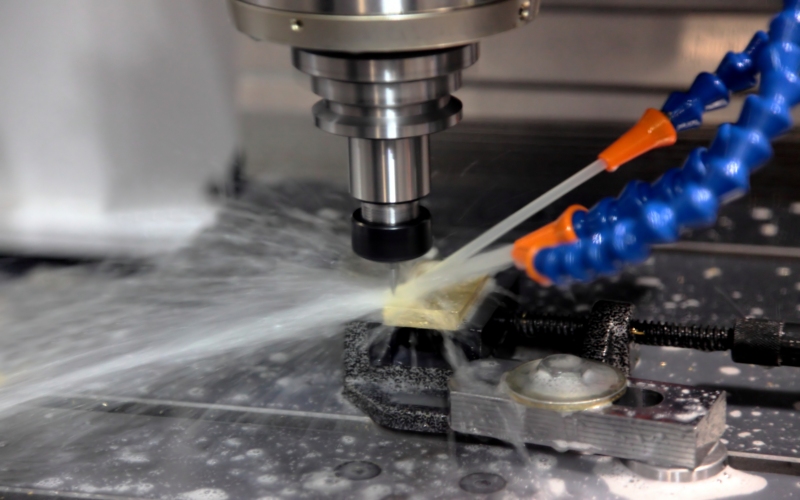

In recent years, frequency inverters are more widely used in industrial washing equipments, which have brought a new technological revolution to the industrial washing equipments. From the earliest semi-automatic washing machine of non-adjustable speed to the full automatic washing machine driven by two double speed motors, and finally it is developed to the multi-rate modern washing machine which is driven by only one motor.

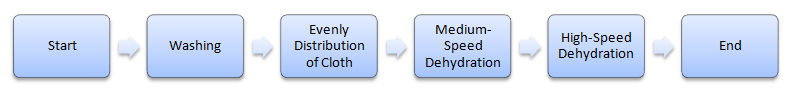

Part 2. Working Process of Industrial Washing Machine

Firstly, add water, and then it washes 25 minutes via reverse rotating and forward rotating. After the washing process finished, it drains water and enter into the dehydration process. The dehydration phase includes 3 processes: evenly distribution of cloth, medium-speed dehydration and high-speed dehydration. In the condition of with water and without water, the industrial washing machine distributes cloth evenly via forward rotating at a high speed (higher than the rotating speed during washing process) for 1.5 minutes so as to let the clothes uniformly attached to the inside of the drum, ensuring that the subsequent dehydration process is smooth. After the drainage, industrial washing machine increases the speed entering into the medium-speed dehydration process (2 minutes) and then the high-speed dehydration process (5 minutes), so the moisture content of clothing is decreased to the required level. The following flow chart shows the working process of industrial washing machine:

Part 3. The Requirements of Industrial Washing Machines

Industrial washing machine requires that frequency inverter can provide high torque, multi-speed, wide voltage range, automatic slip compensation and convenient communication modes. The frequency inverter can work with stable performance, adaptable to the high temperature and high humidity working environment of various hotel laundries, meanwhile, the frequency inverter should meet the specific washing process requirements of industrial washing equipments as well as meeting the service requirements of the specific customer base.

There are two requirements during speed setting process:

(1) Multi-speed way: directly set the speed of each process on the frequency converter.

(2) Communication mode: set the speed of each process via the washing machine dedicated control PC board.

The rotating speed of each washing process of industrial washing machine:

Washing process: 30rpm;

Evenly distribution of cloth: 60rpm;

Medium-speed dehydration: 400rpm;

High-speed dehydration: 700 to 800rpm.

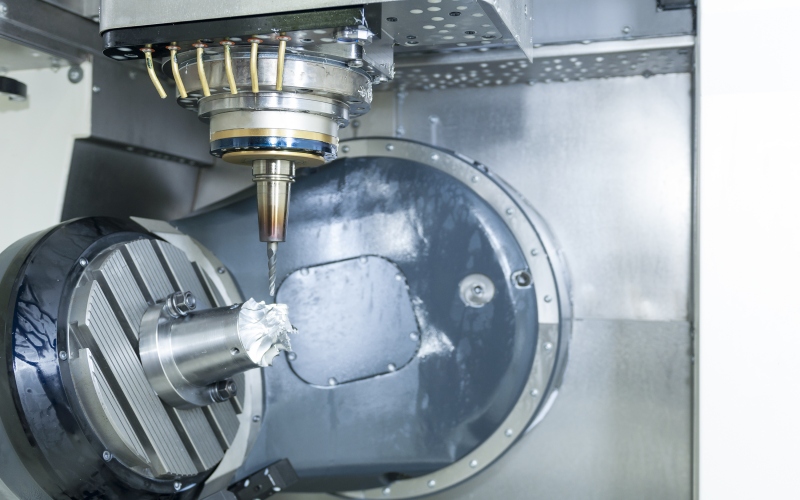

Part 4. Application Characteristics of VEICHI AC70 When Using on Industrial Washing Machine

VEICHI AC70 sensorless vector control inverter features excellent performance, reliable quality, preferential price, simple adjustment, and simple operation. Moreover, it adopts the V/F curve self-regulation technology which is especially designed for industrial washing machine’s technical requirements, so that the industrial washing equipments can start smoothly with low current and stable running performance. This is reason why our AC70 is highly recognized by our customers.

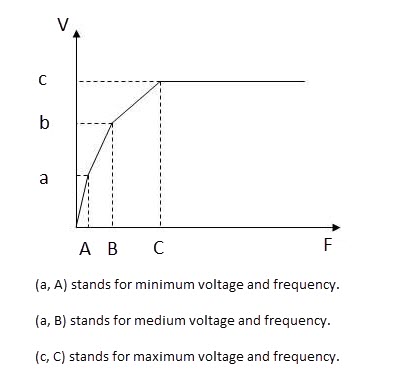

With the special V/F curve automatic promotion function, AC70 can optimize the V/F curve according to the actual needs of each process, besides, it also has powerful multi-velocity function (8-section speed). On industrial washing machines, the V/F curve is generally required as follows:

(A, a) point can be in the origin, the range of A is roughly between 0.00 ~ 4.00Hz, the range of a is roughly between 0 to 25V. Adjusting (A, a) point can influence the device starting torque, thus affecting the washing speed of equipment. If the (A, a) point moves downward, then the starting frequency of washing equipment will be low, and the equipment will start slowly yet stably, requiring that the frequency inverter has large starting torque at low frequency.

(B, b) point regulation directly influences the running current of washing process. If the slope between the points (A, a) and (B, b) is large, i.e., the V/F curve is steep, the operating current will be large. If the slope is too gentle, it will be also not available. Therefore, we need to adjust it according to the practical experience.

Taking 100kg type washing machine as an example:

(A, a) point: 2.00Hz, 24V; (B, b) point: 25.00Hz, 112V; (C, c) point: 50.00Hz, 380V

After the test on the 100kg type washing machine (AC70-T3-11G, 11kW), the data are as follows:

|

Starting Current (A) |

Running Current (A) |

Rotating Speed (rpm) |

Frequency (Hz) |

|

|

Washing |

11.8 |

11.3 |

32 |

7.06 |

|

Evenly Distribution of Cloth |

13.1 |

7.6 |

60 |

11.66 |

|

Medium-Speed Dehydration |

7.2 |

1.9 |

350 |

65.36 |

|

High-Speed Dehydration |

6.7 |

2.8 |

653 |

123.6 |

We got the above data after 2 days of testing during which there was a continuous operation of 4 hours. The two-day test is without any abnormal accident and the temperature rising of frequency inverter is very low. In addition, we got the similar conclusion when testing on 30kg, 50kg and 70kg models. The running current of 100kg automatic washing machine is about 30A that it requires 15kW frequency inverter. Practice proves that VEICHI AC70 plays an important role in reducing the cost of industrial washing equipments, and it is a high-quality inverter suitable for industrial washing equipments.

Part 5. Parameter Setting

|

Function Code |

Function Name |

Set Value |

Function Code |

Function Name |

Set Value |

|

E-00 |

Control mode |

1 |

F-01 |

Multi-section speed 1 |

5 |

|

E-01 |

Running command given channel |

1 |

F-02 |

Multi-section speed 2 |

6 |

|

E-02 |

Main frequency given channel |

0 |

F-30 |

Fault alarm |

1 |

|

E-13 |

Acceleration time |

15 |

H-01 |

Self-set voltage V1 |

15 |

|

E-14 |

Deceleration time |

45 |

H-02 |

Self-set frequency F1 |

4 |

|

E-09 |

Maximum frequency |

130 |

H-03 |

Self-set voltage V2 |

30 |

|

E-10 |

Upper limiting frequency |

130 |

H-04 |

Self-set frequency F2 |

25 |

|

E-17 |

Custom curve |

4 |

H-05 |

Self-set voltage V3 |

100 |

|

E-16 |

Digital setting frequency |

8 |

H-06 |

Self-set frequency F3 |

50 |

|

H-70 |

Communication setting ratio |

1 |

F-10 |

Speed setting of section 2 |

65.36Hz |

|

F-09 |

Speed setting of section 1 |

11.66Hz |

F-03 |

Multi-section speed 3 |

7 |

|

F-11 |

Speed setting of section 3 |

123.6Hz |

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Dejar un mensaje

Dejar un mensaje