- Hogar

- Soluciones

- Application of Veichi AC80 on Sand Saw

Application of Veichi AC80 on Sand Saw Solución

Descripción general

- Descripción general

- Características y Beneficios

- Productos relacionados

- Casos relacionados

- Noticias y eventos relacionados

- Soluciones relacionadas

- Contacta con nosotros

Application of Veichi AC80 on Sand Saw Solución

Características y Beneficios

1. Introduction

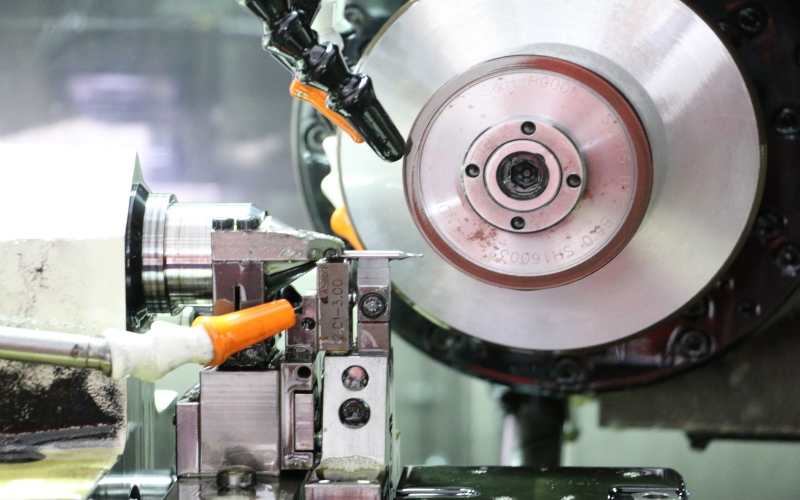

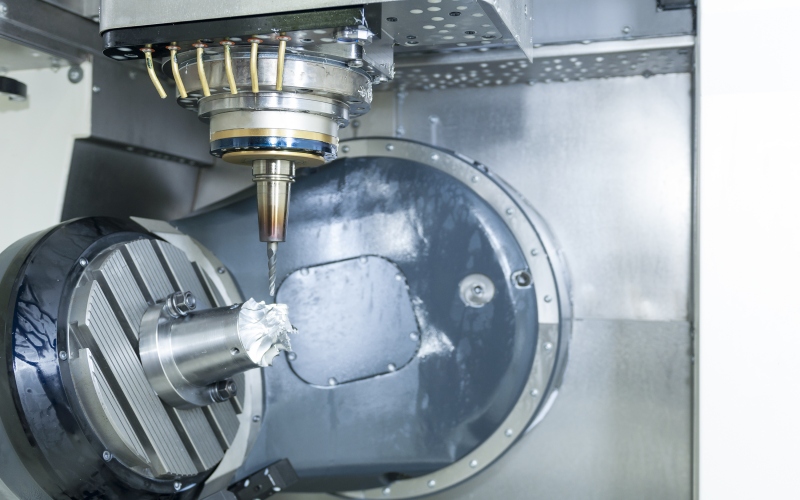

Sand saw application in the stone industry is widespread. Almost all of the stone processing enterprises need sand saw, which has the advantages of processing speed and high product quality.

a. Main problems during the running of sand saw:

(1) How to improve the quality of the board and production efficiency and reduce losses.

(2) How to save high electricity costs.

(3) How to extend the life of sand saws (maintenance period).

b. Existing problems of former sand saw electronic control system:

(1) Due to the imperfection of current equipment, the device can not adjust the speed of the device and the best productivity can not be achieved.

(2) The sand saw motor runs with a star / delta starter mode, and the starting current is huge when switching and the impacts on the grid and equipment are high.

(3) The device speed can not be smoothly adjusted and the processing can not be adjusted according to the material.

2. Sand saw inverter system design and operating principle

The AC80 VFD for single phase and 3 phase motors can transform the sand saws by adjusting the motor running speed, so the sand saw can start with a low speed without current surge.

High speed running during normal condition to improve production efficiency and low speed running when production coming to an end reduce the chance of drawing board. And using the brakes to shorten the stop time when stop or emergency stop, which enables the sand saw to achieve the best results under different working conditions.

3. Sand Saw Inverter System Solutions and Effect

a. Solutions:

(1) Speed change

Increase speed control function without changing the control method of the original equipment. Pressing once would be ok when starting and there’s no need to start several times in a row.

(2) Safety

Grid internal network: the surge voltage dropped significantly, inrush current significantly reduced; grid external network; the excellent end condition would minimize the external network load.

(3) Consumption reduction

Reduce the loss of raw materials consumption and equipment wearing.

(4) Energy-saving

Saving energy and reducing power consumption.

b. Effect:

(1) The original operating system and security protection would not be changed and inverter would be used to regulate the speed. Cut different materials according to the material and processing to improve quality and production efficiency of the board.

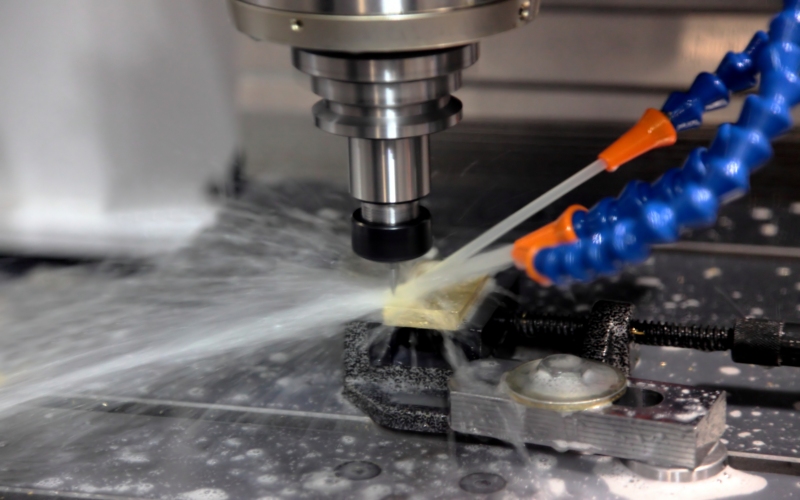

When material cutting begins, turn down the speed, and when the sawtooth completely cut into stones, re-accelerate, and this kind of operation would not cause running mistakes like waves on the slate. When cutting the last ten centimeters, slow down to avoid pulling the plate.

Slow down the speed to avoid impact so the stone would not pull the plate and to reduce losses when cutting rotten material or rock cracks, which can also help enterprises to develop its own unique processing technology in the stone processing industry.

(2) The inverter can reduce the instant surge voltages and inrush current produced during the operation of board cutting machine.

The device start/switch, crank reciprocating internal network surges and transients are less than machines without inverters.

There's almost no vibration on other equipment, which directly reduces the external network load and ensure the electrical safety.

(3) The improved frequency control technology can reduce raw material consumption and costs and improve productivity and competitiveness, reducing the device hard reset hard stop, reduce the wearing of transmission and moving parts.

The speed can be linearly regulated, realizing the synchronization of lubrication system, transmission and moving parts so as to extend equipment service life and reduce repairment times and improve equipment utilization.

(4) Reduce energy consumption, save electricity costs, reduce production costs and improve profitability.

(5) Easy maintenance, this machine is designed dust-resistant, which does not need special maintenance.

4. Precautions for Sand Saw Speed Control

a. Overcurrent problem:

Since the sand saw has great inertia, the start current is relatively large, so the power level of motor drive should be larger than the motor’s power level.

b. Overvoltage problem:

Since the device has a motor flywheel linked with the belt, and then link with the blade Crankshaft, and the flywheel regenerative voltage during operation would cause the inverter overvoltage phenomenon. The DEC/ACC time should be extended or a braking unit and a braking resistor should be added.

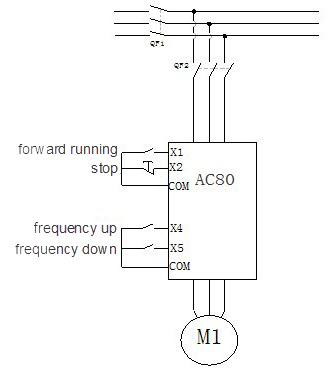

5. Wiring Diagram

6. Conclusion

To sum up, the inverter has much to offer in the stone industry applications, which is also the future direction of technology development.

Frequency inverter is not only energy-saving but also adjustable, thus the product quality and enterprise competitiveness can be greatly improved.

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Dejar un mensaje

Dejar un mensaje