- Hogar

- Soluciones

- Application Case of AC80 Rotary Lathe Control System

Application Case of AC80 Rotary Lathe Control System Solución

Descripción general

- Descripción general

- Características y Beneficios

- Productos relacionados

- Casos relacionados

- Noticias y eventos relacionados

- Soluciones relacionadas

- Contacta con nosotros

Application Case of AC80 Rotary Lathe Control System Solución

Características y Beneficios

Each year the demand for wood continues to grow, while natural resources become scare, so the integrated and efficient utilization of wood resources have become one of the most important issues in woodworking equipment manufacturing.

1. Present Situation of Woodworking Equipment

Currently, the plywood manufacturers adopt traditional card centering round wood cutting machine during the veneer production. This kind of manufacturing method is of high accuracy and good quality. However, due to the existence of central card, when the rotary cutting log diameter is less than 200mm, the card centering round wood cutting machine cannot continue processing. When the round wood diameter is small, the round wood stiffness is reduced that the veneer quality will be reduced. If we discard the remaining wood core or process it into joinery core board, it will cause great waste of raw materials, thereby increasing the cost of veneer production. Therefore, manufacturers commonly use non-card round wood rotary lathe to peel the remaining wood core, so the raw material can be fully utilized.

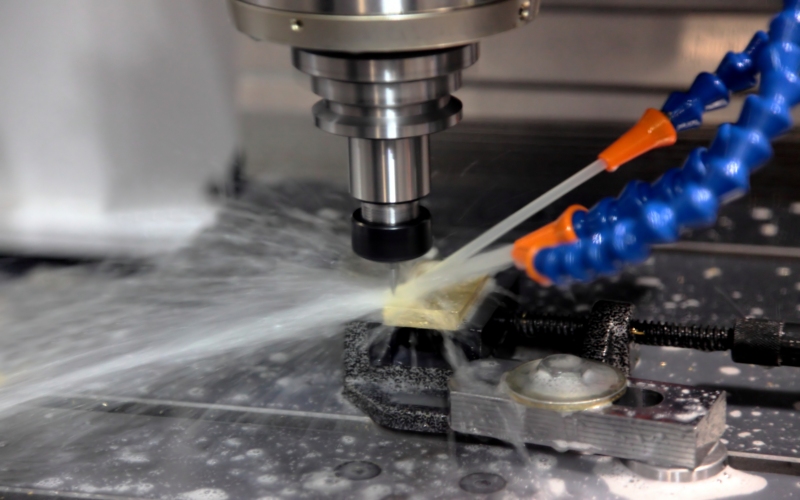

2. Working Principle of Non-card Round Log Rotary Lathe

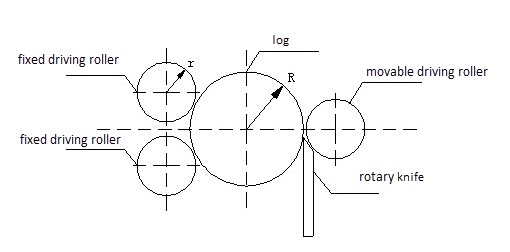

The log rotates, driven by two fixed roll rotation and a moving roll rotation which produces peeling power. The movable roll rotation center bearing and rotary cutter are relatively fixed and moving together, so the peeling knife can peel off veneer from the log.

The veneer thickness is controlled by the moving speed of rotary knife and the gap between movable roller and peeling knife. The gap between movable roller and rotary knife is relatively fixed, which can be adjusted via the blade gap adjustment device. The gap is depending on the thickness of veneer sheet and the moving speed of rotary knife is controlled by the motor speed of control system. Therefore, the moving speed of rotary cutter indirectly determines the thickness of the veneer.

We can see from the below image: the rotational speed of drive roller is constant, that is to say the rotational linear velocity of log is constant. With the change of log diameter, the angular velocity of log is also changed, that is to say the rotating time needed for a circle is also changed accordingly, so the moving speed of rotary cutter is a variable value, a non-linear relationship.

The control of traditional non-card rotary lathe mainly adopts 2T series electromagnetic governor frequency control method that it changes the controller's input voltage via manual adjustment knob or cam curve adjustment in order to change the speed of the motor. The veneer thickness error under this control mode is up to 1mm. Therefore, it is particularly important to design a rotary lathe control system which can accurately control the movement speed of rotary cutter to achieve precise veneer thickness control. The basic design ideas of rotary lathe control system are: A. establish accurate mathematical model. B. Take over the original speed control system to achieve precise speed control.

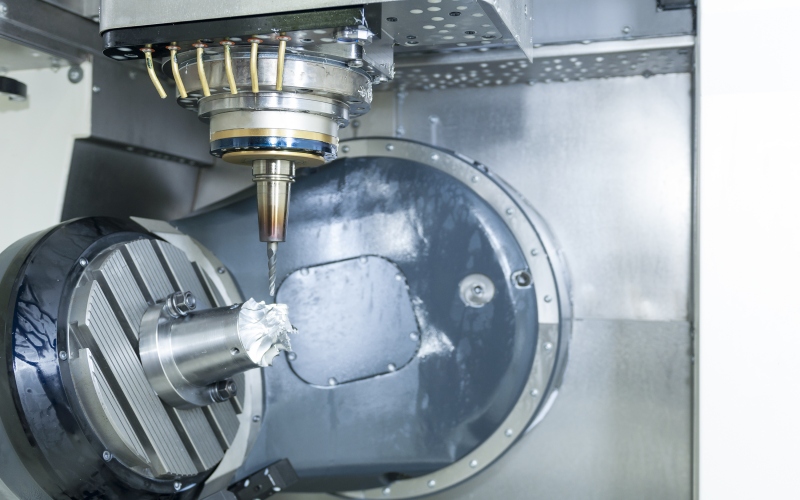

3. Veichi Rotary Lathe Control System

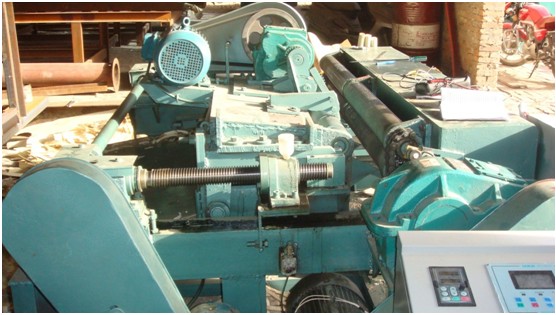

Based on the rotary lathe working principle, Veichi Electric has independently developed a control system which is applicable to various types of rotary lathes on the market. It meets many manufacturers and CNC cutting equipment and automation requirements. Through the practical applications in different provinces such as Shandong, Hebei, Guangxi, Jiangxi and other places, Veichi rotary lathes control system has received many good feedbacks.

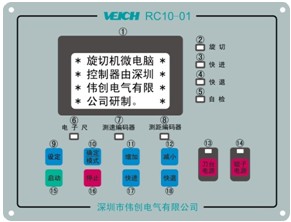

Veichi rotary lathe control system adopts AC80 high performance vector control frequency drive and a dedicated rotary lathe purpose controller. AC80 adopts the latest generation TI DSP chips and innovative three-core design, featuring ultra high-speed operation. 20ms torque response speed, steady-state accuracy error is=3%, speed ratio up to 1: 200, steady speed accuracy error is ±0.2%, and the output torque is 180% of rated torque at 0.5Hz.

Technical Advantages of AC80 used for Controlling Rotary Lathe

1. According to the complex cutting objects, AC80 single phase VFD offers large starting torque ensuring that the motor has a strong yet uniform cutting force at low speed. It also ensures smooth and high-speed in peeling knife stop and restart.

2. Real-time dynamic high-speed computing ability ensures that the veneer thickness is always maintained at the set value, with error less than ± 0.1mm under normal rotary cutting situation. For some mechanical equipment with great lubrication and precise connection process, the thickness error is limited within ± 0.05mm.

3. Superior deceleration brake capacity to ensure instant parking request of turret.

4. Strong adaptability. According to the on-site characteristics of rotary lathe, AC80 has been designed with wide operating voltage range. It maintains a constant output torque in the case of voltage fluctuations, and it can keep woodworking lathe operating normally at 60% of the rated voltage. This technique is particular effective for poor grid environments.

5. Wide adjustable speed range, fast rotary cutting speed, high efficiency, meeting requirements of high speed veneer production occasions.

Features of Veichi Rotary Lathe Controller

1. Using rotary encoder as the distance sensor, its measurement accuracy is up to 0.01mm.

2. Using rotary encoder to measure the actual speed of roller, it avoids veneer thickness errors caused by grid voltage instability.

3. Various kinds of sensor combinations for users to choose from. Whether it is single or dual encoders, the electric foot can operate stably, so it can maximally meet application requirements of new and old customers.

4. It adopts upscale LCD display with richer user interface what displays the working status in real time.

5. It provides various kinds of operating modes to achieve automatic peeling process, effectively guaranteed the personal safety of operators.

6. The built-in switching power supply makes the system more stable with stronger anti-interference ability.

4. Conclusion

Veichi rotary lathe control system simplifies the mechanical structure of traditional woodworking machine, and it eliminates errors due to wear and tear and improves the cutting efficiency and log utilization efficiency. As it is widely used in many areas with thousands of successful application cases, it has gained a high reputation in woodworking industry.

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Dejar un mensaje

Dejar un mensaje